RESIDENTIAL GARAGE FLOOR

Zone Garage offers patented ZG-SHIELD® POLYUREA and polyaspartic garage floor coatings different and superior to any product on the market.

SUPERIOR PRODUCT FOR RESIDENTIAL GARAGE FLOOR

Products for concrete garage floor used by Zone Garage are:

- 3X more resistant to abrasion than 100% solid epoxy

- 100% UV resistant, they never turn yellow

- Can be applied throughout the year regardless of weather

- Completely resistant to the movement of hot tires and almost all common chemicals including calcium, salt, oil, gasoline and grease.

POLYUERA FLOORS |

EPOXY FLOORS |

|

|---|---|---|

| Excellent adhesion | ||

| Durability of 30 years and over | ||

| Very flexible | ||

| Resistant to extreme temperatures | ||

| Dries in one day | ||

| Emit no smell |

POLYUERA FLOORS |

EPOXY FLOORS |

|---|---|

| Excellent adhesion | |

| Durability of 30 years and over | |

| Very flexible | |

| Resistant to extreme temperatures | |

| Dries in one day | |

| Emit no smell | |

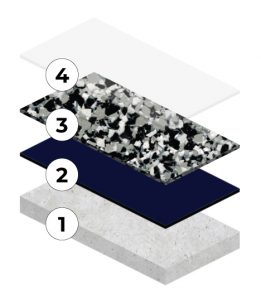

ZONE GARAGE FLOOR COMPOSITION

-

PREPARED SUBSTRATE

-

PIGMENT BASE COAT

-

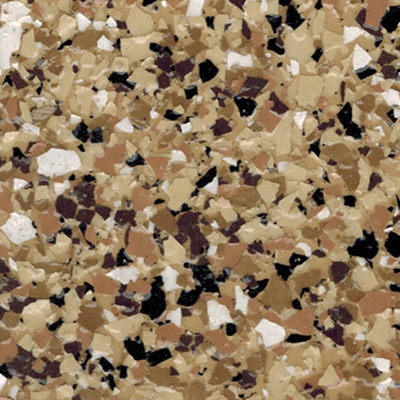

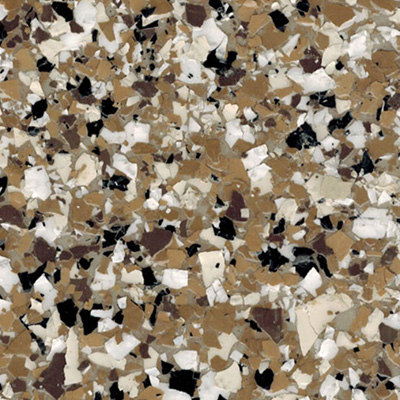

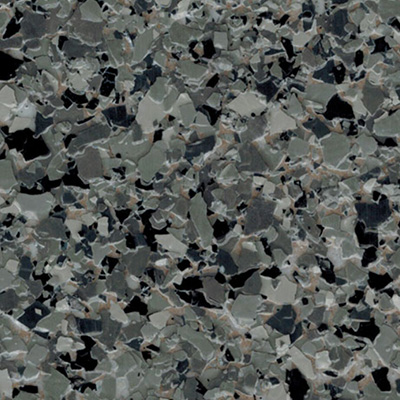

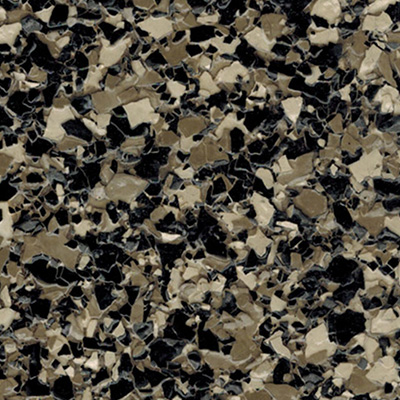

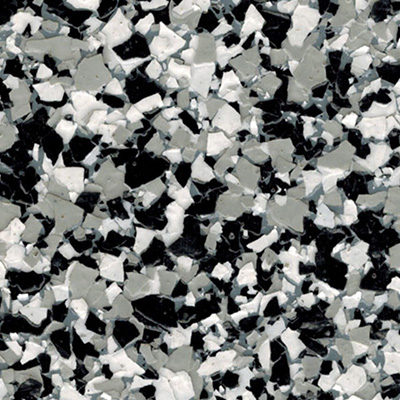

VINYLE CHIPS / FLAKES

-

ZONE GARAGE© CLEAR TOP-COAT

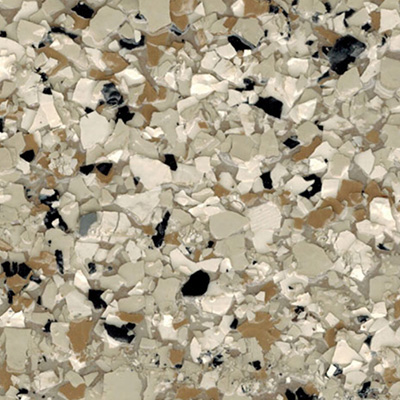

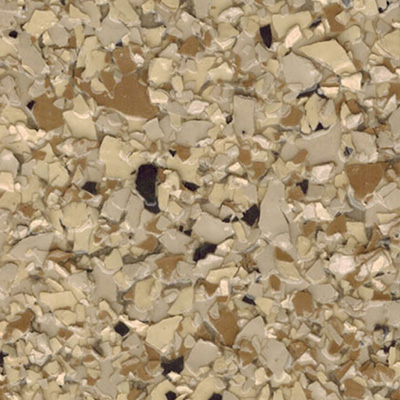

COLORS AND STYLE

Our coatings for garage floor and concrete are available in a variety of solid colors, styles, granite, stains, or as clear sealer to give style to your concrete floor. Our products can also be used as a sealer on acid stained concrete, the polished or colored concrete and even stamped concrete. The most interesting part is that it only takes one day to be installed and be completely dry.

ZONE GARAGE FLOOR COMPOSITION

-

PREPARED SUBSTRATE

-

PIGMENT BASE COAT

-

VINYLE CHIPS / FLAKES

-

ZONE GARAGE© CLEAR TOP-COAT

COLORS AND STYLE

Our coatings for garage floor and concrete are available in a variety of solid colors, styles, granite, stains, or as clear sealer to give style to your concrete floor. Our products can also be used as a sealer on acid stained concrete, the polished or colored concrete and even stamped concrete. The most interesting part is that it only takes one day to be installed and be completely dry.